Oiled or varnished wooden table top? Learn the main differences

Wooden worktops have recently become increasingly popular. They tempt designers and future kitchen users with their warmth and naturalness. Wood always adds cosiness to interiors, is pleasant to the touch and is natural. It is a universal material and can be used in various styles. But what does the use of such a tabletop look like in terms of functionality? What are the main differences in the use of oiled and varnished wood? In the following article, we will try to answer that and share a little bit of our technical knowledge in this aspect.

Varnished table – what do you need to know about it?

Varnished table surfaces have accompanied us for years. We have become accustomed to glossy wood and the opinion that varnish is the most durable method of wood impregnation, which is not entirely true. Lacquer creates a hard coating on the surface and is more resistant to mechanical damage, but it is difficult to renew (it requires intervention on the whole surface), peels off and is flammable.

Oiled wooden table – what do you need to know about it?

Oil, on the other hand, is an ecological product made of natural resins and waxes, it extracts and emphasizes the individual characteristics of wood, absorbs into the wood, protecting it also deep inside, and copes well with high temperatures. Oiled surfaces such as wooden kitchen table tops or wooden dining tables can be used intensively. However, you have to be patient at the beginning and maintain them more often, then you can be sure of full impregnation. The advantage of this technique is also the fact that if a scratch, stain or discolouration occurs during use, it can be repaired in spots and by yourself. All you need is a piece of sandpaper and oil on the tabletop again. Such a wooden table can serve in good condition for many years.

Oil vs varnish dining table – technical aspects

Pure wood oils:

There are two types of wood oils – drying oils and non-drying oils. In my opinion, drying oils for wood are the only valid finishing oils. They start as liquids, but they harden into solid film. For me, that’s the definition of a finish.

Non-drying oils are usually vegetable (peanut, olive, corn, coconut, rapeseed) or mineral oils obtained from petroleum. Orange and lemon oil, typically mineral oil with an added citrus scent, also belong to this group.

These do not form a film but remain moist for an indefinite period of time. They can get rid of anything that comes into contact with the oiled wood and they will soon be washed off with soap and water.

The application of vegetable or mineral oil to wood is therefore not a final treatment, but a wood treatment, and a temporary one.

Wood table varnish:

If the oil contains only one ingredient, the varnish contains resin and solvent. For example, traditional spar varnish contains tung oil, phenolic resin and solvent spirit or naphtha. The most common varnish resins, alkyd and polyurethane, can be produced by chemical modification of linseed oil.

Despite their name, Danish oil and teak oil are not oils, but thin lacquers. Manufacturers call them “oil” because they are to be used just like oil. The truth is that you can apply any oil varnish in the same way as pure oil: Flood it, wipe it all off and repeat the process with one coat per day until you get the desired build.

Måne White Round Table

Hard Wax oil finish (clear matt) on Måne White Round Table

Virkerå oak coffee table

Structured spruce wood with light natural oil finish on Virkerå oak coffee table

Basic FEM oak wood dining table

Bleached solid oak table top with a natural oil finish on BASIC FEM oak wood dining table

High-quality oiled oak tables in the SFD Furniture Design shop

I hope I have convinced you to choose dining tables with oiled tops. By opting for this type of table you will certainly be fully satisfied with its appearance and functionality. Thus, you will gain a wonderful oiled table for your Home for many years to come. So if you want to find your dream dining table with an oiled top or an oiled coffee table – visit our SFD shop and choose a variant that particularly appeals to you!

In case of any further questions do not hesitate to contact us.

We invite you to read also:

_______

Artur Bieńko

SFD Furniture Design

#WLCM_HOME #WLCM_CRAFT #WLCM_DESIGN #WLCM_NATURE

HAVE YOU SEEN THESE?

Why us? SFD Furniture Design’s brand values make our solid oak furniture unique

You can get the best custom furniture designs developed into classy yet fitting for your interiors. In SFD brand we design and create s…

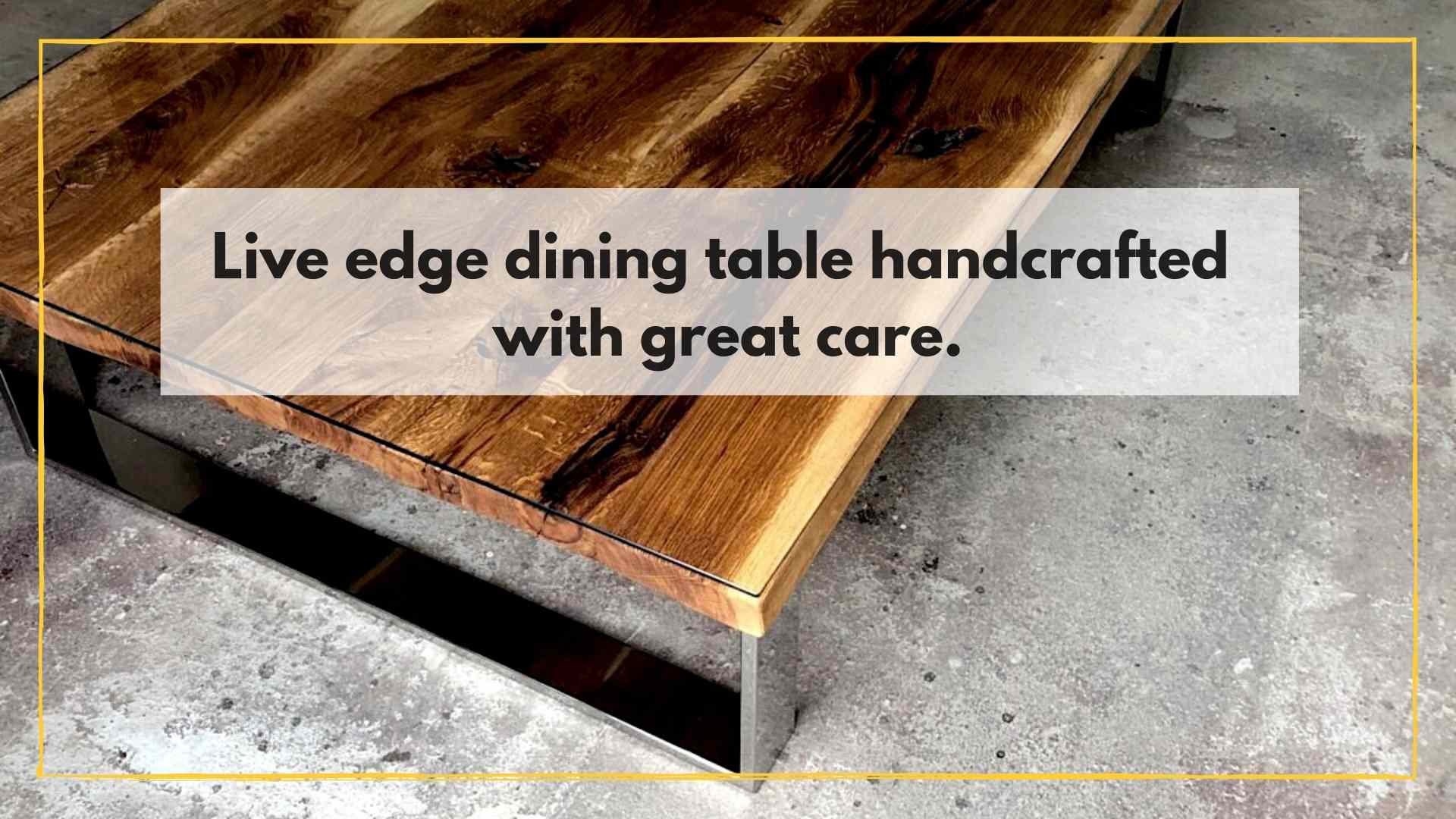

Live edge oak dining table handcrafted with great care

Handmade live edge dining table of the highest craftsmanship quality. Learn its story! Learn more and check out our SFD Furniture Desig…

Ideal table for small spaces

Discover the ideal table for small spaces! Explore the benefits of chic round, square, and rectangle designs, creating a unique space t…

OUR PRODUCTS

VIRKERÅ live edge oak coffee table

€ 1.970

MÅNE WHITE Round non-/extendable table

€ 1.270 – € 1.970

BASIC FEM bleached oak wood dining table

€ 890 – € 2.020